AstenJohnson is committed to meeting or exceeding regulatory requirements from OSHA, CCOHS, EASHW and the China Workplace Safety Law.

Safety Teams and Safety Leaders are the go-to resource for each associate to make sure they have all updated safety policies and have completed mandatory training.

Our Field Sales and Service associates complete TAPPISAFE standardized training for the Pulp and Paper Industry.

Safe work procedures are an important component of our ZAC safety system. Review and feedback from our shop floor associates performing the work tasks is a critical part of defining safe work procedures.

The team in China reduced ergonomic risks by using a motorized winch at a workstation, rather than a hand winch.

BEFORE

AFTER

We are proud to announce that one office Our US sites has once again earned its SHARP (Safety & Health Achievement Recognition Program) re-certification, a significant milestone in workplace safety excellence.

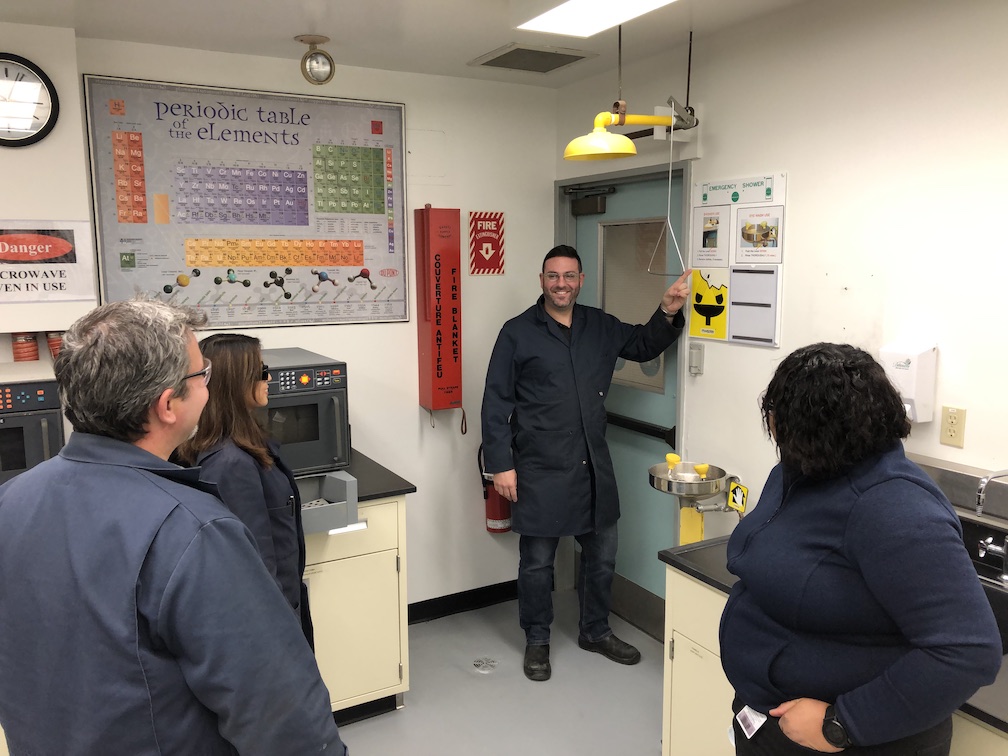

Administered by OSHA, SHARP recognizes businesses that maintain exceptional safety and health programs, going above and beyond regulatory requirements. This achievement reflects the hard work and dedication of our entire team in fostering a culture of safety, reducing workplace hazards, and prioritizing employee well-being.

This site was first SHARP certified in 2009, through a partnership with VT Project WorkSafe.

AstenJohnson's Clinton, SC facility has successfully completed its annual Safety Environmental Team (SET) audit for the 8th consecutive year. The audit, a critical part of our ongoing commitment to safety and operational excellence, was conducted with the goal of evaluating the effectiveness of our safety protocols, environmental management practices, and training programs.

This facility demonstrated exemplary compliance with safety standards. The audit team praised the proactive steps taken to identify and mitigate potential hazards, including the installation of new safety guards and the implementation of enhanced lockout/tagout procedures. Employees were commended for their vigilance in maintaining a culture of safety and adhering to the company’s protocols.