Our new site in Waco, Texas, reached the milestone of 365 days without a recordable incident on February 7, 2024! We started assembling one of our lines the moment the equipment arrived with the help of a handful of associates. The working conditions at the time were far from ideal since the building was not completed. As the size of our team grew over the next several months, it was encouraging and reassuring to see our associates embrace our ZAC™ culture, even if the environment was not as safe as we would have liked it to be. We are very thankful for our associates’ commitment to making our site safer on a daily basis.

AstenJohnson’s safest sites are also the ones with the most documented near misses. What Is a Near Miss?

A near miss is an unplanned event that had the potential to cause injury or damage but, fortunately, did not. It’s the slippery step that didn’t result in a fall, the unsecured load that shifted but didn’t collapse, or the forklift that stopped just in time. These moments might seem minor, but they are warning signs that something could go wrong in the future if left unaddressed.

The reality is that near misses happen every day, whether we acknowledge them or not. The difference between a near miss and a recordable injury can be as simple as luck, timing, or quick reflexes. Relying on luck is not a sustainable safety strategy, which is why reporting near misses is so critical.

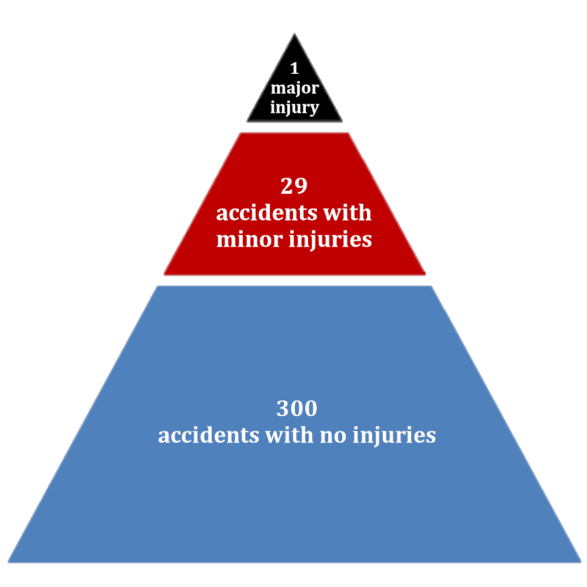

The Accident Triangle, also known as Heinrich’s Triangle or Bird’s Triangle, demonstrates the relationship between minor incidents and serious injuries. Research shows that for every 1 serious injury, there are typically 29 minor injuries and 300 near misses or unsafe acts. This means that if we focus on addressing and reducing near misses, we can prevent minor injuries and, ultimately, severe accidents. Near miss reporting allows us to intervene early and break the chain of events that could lead to a serious injury.

ZAC Safety applies also for our extensive network of field- based Sales and Service associates. Whether traveling to or performing work at our customer’s facilities, our team members have a digital app to guide them safely in their work, and to provide assessment feedback.

The app contains tabs for Job Hazard Analysis (JHA) guidance for work tasks, incident reporting, vehicle safety and care, and content related to safety in the work environment commonly encountered.

With the AJSafetyCheck app, AstenJohnson field-based Sales and Service are always well connected with ZAC Safety.

Our North America Paper Machine Clothing Field Team reached an outstanding milestone: November 2, 2024 marked three years since the team last experienced a recordable safety incident.

This achievement showcases their unwavering personal commitment to safety and teamwork. Every member has contributed by prioritizing safe practices and looking out for one another. Whether double-checking equipment or stepping in to help a colleague, their dedication to safety is evident in every action.

While we celebrate this impressive accomplishment, we know our work is ongoing. Our goal remains to sustain and build upon these safety practices across all teams. Here’s to many more safe years ahead!

AstenJohnson Clinton recently hosted an SCMEP OpExChange event to showcase the site’s work with our ZAC Safety System. The OpExChange is a large group of South Carolina manufacturers who best practice share topics related to manufacturing. The event was attended by 26 people from 18 different companies. Scott Dudley and his team were able to proudly share the ZAC Safety360 work the site associates have collaborated on, and to showcase their facility, associates, products, and safety systems for the event participants.

Associates in our Charleston facility volunteered for a road clean-up around the office. Before anyone went outside, the group was given safety gear including high visibility vests and gloves, as well as training for staying safe on the road and not lifting heavy or dangerous items. Associates worked in small teams along the street and the nearby landing, keeping each other safe by watching traffic and ensuring that garbage was safely in bags, without risk of falling out. The event was a success in terms of both cleaning and safety.